1000LPH RO Plant : Helping a Kuwaiti Client’s First China Procurement

1. Initial Contact: Behind the Inquiry for 1000LPH Reverse Osmosis plant

Lies the Confusion of a First-Time Purchase

On June 30, 2025, Mr. M from Kuwait sent his first message, getting straight to the point: “Quote for 1000LPH Reverse Osmosis plant, CIF Shuwaikh Port.” He immediately followed up with, “The port is indeed Shuwaikh Port,” his caution evident even in the punctuation.

As our conversation progressed, I quickly learned the details: this was his first time procuring equipment from China, so he had a vague understanding of all procurement processes—only confirming that he needed “the equipment safely delivered to Kuwait, capable of treating local well water for irrigation purposes.” He also provided key raw water conditions: “Feed water: Brackish Ground Water from a well (about 11350PPM).” Instead of rushing to send a quotation, I first addressed his confusion: “Is this your first time purchasing from China? No worries. Based on the 11350PPM brackish water condition you mentioned, I will oversee the technical adaptation and logistics clearance of the 1000LPH Reverse Osmosis plant from start to finish. I’m preparing the quotation now—let’s sort out the key issues first to ensure your peace of mind.”

2. Technical Adaptation: Customization for Raw Water and Voltage Verification of 1000LPH Reverse Osmosis plant

(1). 1000LPH Reverse Osmosis plant: Targeted Adaptation to 11350PPM Brackish Water

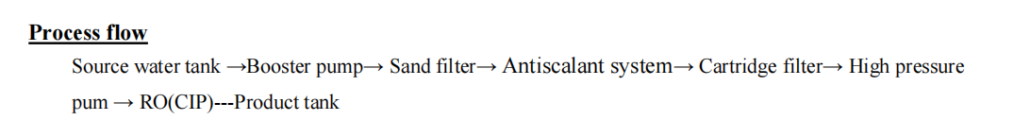

The 11350PPM brackish well water mentioned by Mr. M, though less saline than seawater, has high levels of calcium, magnesium ions, and suspended solids, which easily cause RO membrane scaling and clogging. To address this, I designed a customized solution specifically for the 1000LPH Reverse Osmosis plant: “This 1000LPH Reverse Osmosis plant will be equipped with a three-stage pretreatment system of ‘Quartz Sand Filtration + Activated Carbon Filtration + 5μm Cartridge Filter’ to first remove suspended solids and organic matter from the water. It will also be paired with an antiscalant dosing device to prevent membrane scaling at the source. The core RO membrane uses a pollution-resistant polyamide composite membrane with a stable desalination rate of 99.2%. The treated water will have a TDS of only 293.7ppm, fully complying with WHO drinking water standards and suitable for production, daily use, and your irrigation needs.”

(2). 1000LPH Reverse Osmosis plant: Accurate Voltage Adaptation from 220V to 380V

Initially, Mr. M clearly requested a “220V voltage.” However, considering the 7.75KW power of the 1000LPH Reverse Osmosis plant and the conventional industrial power standards in the Middle East, I keenly sensed a potential issue and asked patiently: “Will the 1000LPH Reverse Osmosis plant be used in an industrial or civilian setting? Treating 11350PPM raw water requires stable power support—220V civilian voltage may not drive the equipment. Industrial power supply in Kuwait is usually 380V/3-phase; I recommend confirming with an electrician.”

Shortly after, he replied: “The electrician verified it’s 380V—I made a mistake earlier!”

I immediately shared the solution: “No problem. I will adjust the voltage configuration of the 1000LPH Reverse Osmosis plant to 380V/50Hz, while reserving a dual-voltage switching module for flexible adaptation to 220V if needed later. Additionally, your local plugs are Type G, right? The junction box has been pre-equipped with an adaptive interface, and the thickness of the grounding plate is manufactured in accordance with local standards—just plug it in and use it.”

After reading this, he praised sincerely: “You’re extremely professional. I didn’t even consider details like raw water adaptation and voltage for the 1000LPH Reverse Osmosis plant. I really made the right choice by contacting you.”

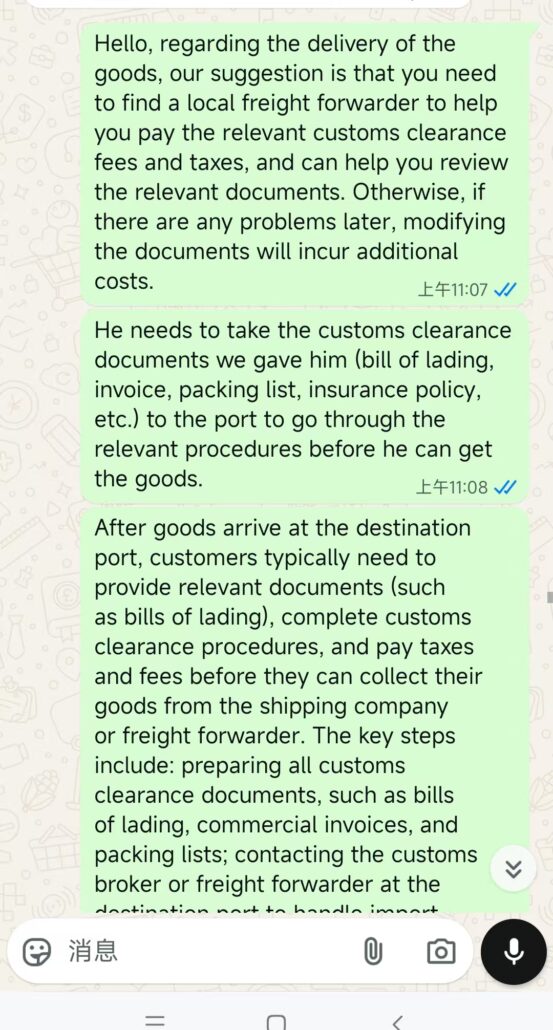

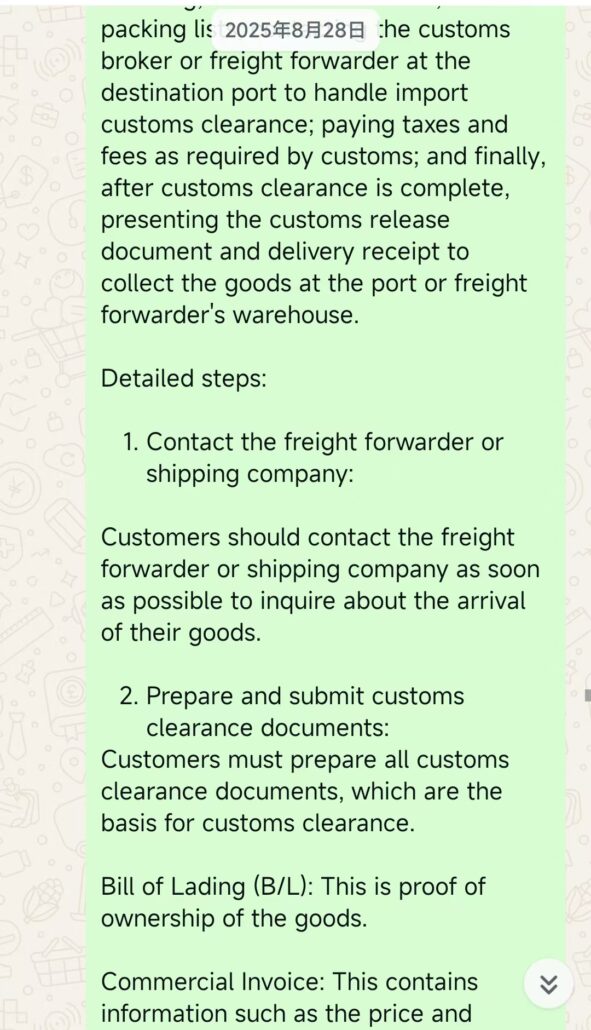

3.Process Breakthrough: Procuring 1000LPH Reverse Osmosis plant—Easy Customs Clearance Even Without a Freight Forwarder

—Easy Customs Clearance Even Without a Freight Forwarder

Step 1: Lock in a Reliable Local Freight Forwarder in 1 Day

First, I told him: “Search ‘Shuwaikh Port customs broker’ on Google. Pick options with water treatment equipment clearance experience. I’ve gathered contacts for 3 reliable Kuwaiti forwarders—send them this inquiry directly:

‘Need to clear a 1000LPH Reverse Osmosis plant (treats 11350PPM brackish well water, for irrigation). HS Code 84212100, CIF Shuwaikh Port—please quote clearance fees.’

Note the equipment’s purpose and raw water details; this helps the forwarder handle the process accurately.”

Step 2: I’ll Prepare All Customs Clearance Documents

Step 3: Key Tips for Pickup & Installation

Finally, I reminded him: “Pick up the 1000LPH Reverse Osmosis plant within 7 days of port arrival to avoid demurrage fees. Once the forwarder clears customs, they’ll give you a ‘release order’—use this to collect the unit from the port warehouse.

The equipment comes in a fumigation-free wooden case, so you can forklift it straight to your site. During installation:

- I’ll share the pretreatment system’s sewage outlet location

- I’ll note the RO membrane’s correct installation direction

I’ll also tweak the optimal operating settings (tailored to 11350PPM raw water and irrigation) to keep your water supply stable.”

4.Successful Delivery: 1000LPH Reverse Osmosis plant Handover with Trust Throughout

On August 30, 2025, the 1000LPH Reverse Osmosis plant was produced and packed as scheduled. I immediately sent photos of the forklift loading the container to Mr. M, along with a notification: “The wooden case has been affixed with the Kuwaiti customs code label for quick clearance by the freight forwarder. Targeting your 11350PPM brackish water and irrigation scenario, I have additionally sent 1 set of spare antiscalant and cartridge filter elements for easy replacement and maintenance later.”

He replied with a lengthy thank-you: “From the raw water adaptation and voltage confirmation of the 1000LPH Reverse Osmosis plant to helping me find a freight forwarder and prepare customs clearance documents, you have been patient and professional throughout, considering every detail thoroughly. This is my first time purchasing equipment from China—I originally worried about various issues, but the process was much smoother than I imagined. Thank you so much!”

After the plant arrived at the port, Mr. M completed customs clearance and pickup as guided. On the same day, he sent photos of the equipment at the site and a water production video: “The 1000LPH Reverse Osmosis plant has been installed. Operating according to the parameters you provided, it handles the 11350PPM well water perfectly. The produced water is clean and the operation is stable—it works great for irrigation. I will only purchase water treatment equipment from you in the future!”

Why Choose Me for Your First 1000LPH Reverse Osmosis plant Procurement?

For clients purchasing 1000LPH Reverse Osmosis plant from China for the first time, I understand your fears of “mismatched technology, complex processes, and lack of after-sales support”:

- Technical Customization: Precisely match raw water conditions (e.g., 11350PPM brackish water) and customize equipment components based on usage scenarios (e.g., irrigation, production). Verify local voltage and plug standards to ensure the 1000LPH Reverse Osmosis plant is ready for use upon delivery.

- Process Escort: No freight forwarder or unfamiliar with customs clearance? I break down steps, provide resources, and draft communication scripts, clarifying HS codes and equipment purposes to simplify complex procurement.

- Full-Cycle Support: Available 18 hours a day from inquiry to after-sales. Anticipate potential issues in advance and provide additional spare parts adapted to raw water and usage scenarios, ensuring a worry-free procurement experience for 1000LPH Reverse Osmosis plant.

- If you are also purchasing 1000LPH Reverse Osmosis plant for the first time, or struggling with “raw water adaptation, technical parameters, or freight forwarder/customs clearance,” contact me now—Bella | Mob& Wechat& WhatsApp: (+86)13544774483 I will use the same professionalism and patience to make your first procurement from China a smooth journey