126m³/hr Reverse Osmosis Water Treatment For Irrigation

Because the client faced significant challenges with poor water quality unsuitable for agricultural irrigation:

Raw water pH: 7.27

Electrical conductivity: 5.17 ds/m (5170 ppm TDS)

Sodium content: 39.86 mg/L

High total dissolved solids exceeding irrigation standards

Technical Solution:

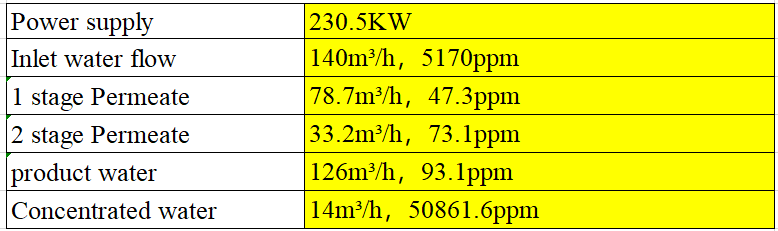

So Based on the client’s irrigation and planting needs, and the requirement to increase the recovery rate to 90%, the engineers used a two-stage purification process, returning the concentrated water from the first stage back to the feed water tank before the second stage of purification,Our Engineer design below :

The project implemented a comprehensive two-stage RO system with the following process flow:

-

Raw water pump with 30KW power, SS304 material construction, equipped with Vicruns 30KW frequency inverter

- Multimedia filters: 3 units with dimensions Φ2200×3600mm, constructed of carbon steel with rubber lining

- Antiscalant dosing system for membrane protection

- Precision filter with 5/1μ filtration capability

RO Treatment Stage:

First Stage RO:

- High-pressure pump system with automatic control

- RO membrane modules integrated with CIP (Clean-in-Place) cleaning function

- Permeate water production: 78.7 m3/h with TDS level of 47.3 ppm

Second Stage RO:

- Booster pump system for pressure stabilization

- Secondary antiscalant dosing system

- RO membrane modules with independent monitoring

- Permeate water production: 33.2 m3/h with TDS level of 73.1 ppm

Post-treatment and Distribution:

- pH adjustment unit to optimize water quality for irrigation

- Product water storage tank with level monitoring

- Concentrate water discharge system handling 14 m3/h of brine with TDS level of 50861.6 ppm

- Comprehensive piping system with valves and Shllj SS304 pressure gauges

Key Components and Specifications:

The system incorporates high-quality components from reputable brands to ensure reliability and performance:5.Control Systems:

30KW frequency inverters provide precise speed control for energy efficiency,with PLC and touch screen it can enable automatic operation and monitoring.

Project Implementation and Results:

Total power consumption of the system is 230.5KW, optimized for energy efficiency while maintaining performance requirements.

The project was completed within the scheduled 4weeks production cycle, followed by thorough commissioning and testing.

Strict quality control measures were implemented throughout the manufacturing, installation, and testing phases to ensure compliance with specifications.

Contact Us

For more information about our Large Scale Water Purification Systems, customized solutions, or quotes, pleasecontact our professional team, We provide tailor-made solutions to meet vour water treatment needs

Contact Information

Email: eva@swroplant.com

Phone: +86 135 3283 6525