135m³/hr Reverse Osmosis Irrigation Water Treatment

1.Background:

1.Located in Canada—renowned for premium grape cultivation and wine production 82.36-acre grape plantation. Grapes demand stable, high-quality irrigation, requiring watering every 7–10 days during key growth phases .However, local raw water fails to meet grape irrigation standards: with 5.17dS/m electrical conductivity, 39.86mg/L sodium, and high TDS. Long-term use of this high-salinity water .To solve this, dongguan hiayuan water treatment reliable solution delivering consistent low-salt irrigation water (EC < 1dS/m) to meet the 82.36-acre plantation’s large demand. This led to the collaboration on the 135TPH reverse osmosis (RO) irrigation water treatment project.

2. Raw Water & Product Water Requirements:

2.1 Raw Water Quality Parameters:

pH Value :7.27

Electrical Conductivity:5.17ds/m

Sodium Content:39.86mg/L

Raw Water Requirement:lear and transparent, no obvious pollutionsuspended solids, turbidity and otherindicators need to be stable)

2.2 Product Water Standards:

Core Water Quality Index:Electrical Conductivity< ldS/m(Meetsagricultural irigation water requiremnents:135m3/hr (81.1ppm)

Water Production Capacity:Application Scenario:Farmland irrigation water supply

3.Reverse Osmosis (RO) Process Solution:

Three Φ2200×3600 carbon steel filters connected in series, along with three sets of electric butterfly valves, enable precise on/off control, flow regulation, and system protection of the water flow in the pipeline, suitable for high-flow irrigation of 135 m3/h. After media treatment, chemical scale inhibition extends the lifespan of core equipment, ensures stable water production, and improves TDS water quality. Using 84 ULP22-8040 and 36 FR12-8040 membranes of different models, it meets the requirement of EC < 1 dS/m for grape irrigation while reducing costs and avoiding frequent membrane cleaning that could disrupt the irrigation cycle.

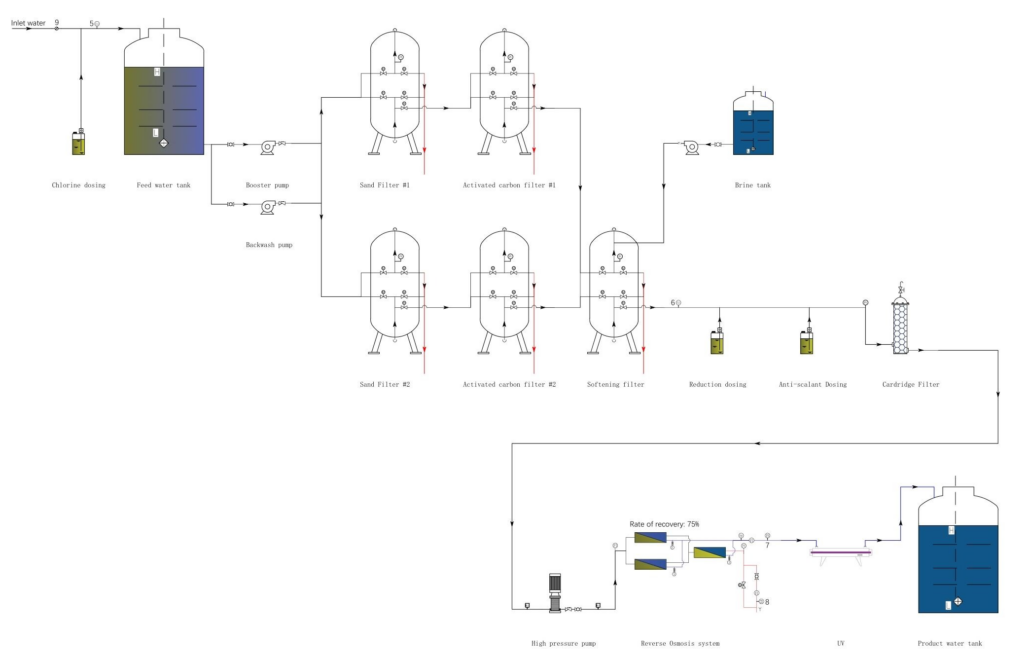

Our design process flow is as follows:

3.1 Process Flow

Adopting “Pretreatment + Reverse Osmosis” core process, the specific flow is as follows:

Raw Water Pump (with frequency conversion control) → MultimediaFilter → Antiscalant Dosing Device → Precision Filter → High-Pressure Pump → ROSystem (with CIP Cleaning) → pH Adjustment Device

4.Project Advantages:

1. Efficient Desalination: RO system has stable desalination rate, ensuring product water conductivity < 1dS/m, which meets irrigation water standards

2. Stable Operation: Equipped with frequency conversion control and pressure difference monitoring devices to adapt to raw water quality fluctuations

3. Energy-Saving Design: Key equipment adopts high-efficiency motors, 184KW total power matches 135m3/h water production capacity, optimizing energy consumption ratio

4. Easy Maintenance: Equipped with CIP chemical cleaning system, facilitating daily maintenance of RO membranes and extending equipment service life.

Contact Us

For more information about our Large Scale Water Purification Systems, customized solutions, or quotes, pleasecontact our professional team, We provide tailor-made solutions to meet vour water treatment needs

Contact Information

Email: eva@swroplant.com

Phone: +86 135 3283 6525