21 questions for solve RO water treatment system produce bottle water

Background Introduction

“When Lebanese client Ahmed inquired about a 500LPH RO water treatment system for bottled water on December 3, 2025, we didn’t expect the collaboration’s breakthrough would be 21 detailed questions—focused on cross-border procurement pain points like pipeline materials, brand reliability, and quantified parameters.”

Step 1: Initial Quotation – Covering the Basics of Bottled Water RO Water Treatment System

“Is the raw water groundwater with TDS 350-600ppm? Is it for drinking water? 500LPH output? And Lebanon uses 220V voltage, right?”After confirming 4 core parameters within 1 hour, we sent the first quotation that afternoon at 5 PM—but this wasn’t a “random” proposal. Instead, it directly addressed Ahmed’s two key concerns:

“Do you only supply RO systems, or do you include pre-filtration?”

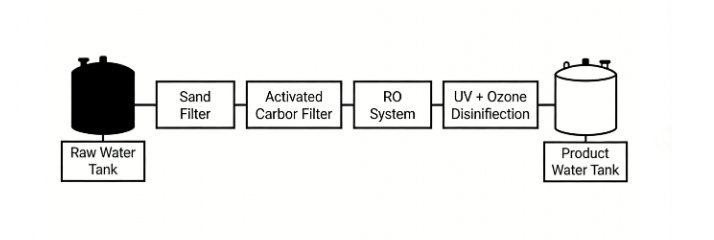

The quotation clearly covered the full process: Raw Water Tank → Sand Filter → Activated Carbon Filter → RO System → UV + Ozone Disinfection → Product Water Tank, with a note: “Not a standalone RO device, but a complete RO Water Treatment System”—immediately resolving his worry about “system completeness.”

“Do you supply filling machines?”

We responded honestly: “Our expertise is water treatment equipment; filling machines are not our strength,” while adding: “We can recommend long-term partner filling machine suppliers”—avoiding overpromising while demonstrating ongoing service support.

The core of this initial quotation was to first “meet the basics of the requirement,” using a clear process and transparent response to show Ahmed: “We understand what you need.”

For RO system technical standards, refer to ISO 13923 (Water treatment equipment safety requirements).

Step 2: 21 Key Questions – The Pain Points of Cross-Border RO Water Treatment System Procurement

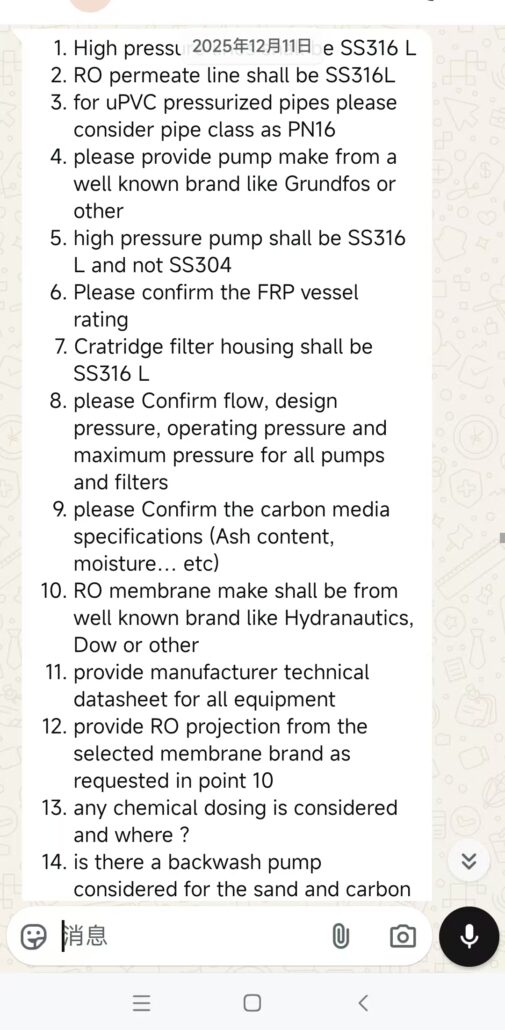

Six days later, after returning from a business trip, Ahmed sent 21 “detail bombs”—no pleasantries, just “soul-searching” questions about equipment reliability:

1.Must high-pressure pipelines be SS316L, not regular stainless steel?”

2.Should RO permeate pipelines also be SS316L?”

3.Should uPVC pressure pipes be class PN16?”

4.Pumps must be well-known brands like Grundfos—no generic brands?”

5.Should high-pressure pumps be made of SS316L, not SS304?”

6.What is the rated pressure of FRP vessels? Can they withstand long-term operation?”

7.Should cartridge filter housings also be SS316L?”

8.Do I need specific values for flow, design pressure, operating pressure, and maximum pressure for all pumps and filters?”

9.What is the ash content and moisture of the activated carbon? Don’t use low-quality carbon?”

10.Should RO membranes be from brands like Dow or Hydranautics?”

(The remaining 11 questions: technical manuals, RO membrane projection data, chemical dosing, backwash pumps, media lifespan, UV dosage, ozone specifications, interlock automation, flow/pressure analyzers, food-grade coatings, CIP systems…)

Each of these questions hit the core pain points of cross-border water purification equipment: inadequate materials → corrosion and leaks; unclear branding → difficult maintenance; unquantified parameters → unguaranteed water quality. Ahmed didn’t want a “functional device”—he wanted a solution that was safe to use, durable, and compliant with local Lebanese water quality standards.

Step 3: Revised Quotation – Customizing the RO Water Treatment System to Solve All Concerns

Instead of just saying “no problem” to the 21 questions, we split the quotation into Resolved Items + Pending Items + Inapplicable Items to demonstrate professionalism through “precision matching”:

For “material/brand requirements”: Directly implement in the quotation

Replaced the high-pressure pump with the Grundfos CR series (noted: “IE5 high-efficiency motor, IP55 protection class”), specified the RO membrane as Dow LCLE-PRO-4040 (attached original factory parameter sheet), upgraded high-pressure pipelines, permeate pipelines, and filter housings to SS316L, and adjusted uPVC pipes to PN16—each modification was marked “Upgraded per client request” in the quotation’s “Configuration Details” section.

For “quantified parameter requirements”: Provide specific values, no ambiguity

FRP vessel rated pressure: 10bar (up from 8bar); activated carbon: ash content ≤5%, moisture ≤10% (attached test report excerpt); UV disinfection dosage: 40-60mJ/cm² (noted: “Compliant with WHO drinking water disinfection standards”); pump flow/pressure: clearly stated as “500LPH, design pressure 1.2MPa, operating pressure 0.8-1.0MPa”—replacing “no problem” with “specific values + rationale.”

For “inapplicable items”: Be transparent, don’t force fit

Clearly noted: “Chemical dosing, backwash pumps, and flow/pressure analyzers are not included (client requires a small bottled water system; these configurations are only necessary for large industrial systems)”—adding: “Can be installed later if production expands; not required for the current system”—avoiding unnecessary costs for the client.

For “technical document requirements”: Attach 5 original factory documents

Along with the quotation, we sent the Grundfos pump data manual, Dow RO membrane specification, UV disinfection technical document, ozone system manual, and FRP vessel test report—each corresponding to Ahmed’s questions (e.g., the UV dosage document noted: “40mJ/cm² corresponds to 99.99% inactivation rate”).

Final Outcome: Why Detailed Responses Win RO Water Treatment System Collaborations

After sending the revised quotation, Ahmed’s response was simple: “Well noted. I will check everything and come back to you”—no exaggerated praise, but this calm reply was recognition that all 21 questions had been addressed item by item.

The core of this collaboration was never “how much the price was reduced,” but “we addressed every one of your concerns with professionalism”: Ahmed tested “whether we truly understand water purification” with 21 questions; we proved “we understand not just the equipment, but why you care about these details” through two quotation iterations.

Collaboration Insight: For Cross-Border Technical Business, “Addressing Details” Matters More Than “Low Prices”

For cross-border technical businesses like water purification equipment, a client’s “meticulousness” isn’t nitpicking—it’s “fear of pitfalls.” The value of a quotation is never just “price numbers,” but “proving with details: we know what you’re worried about, and we can solve those worries.”

From the initial quotation’s “meeting the requirement” to the revised quotation’s “resolving concerns,” the two iterations were essentially a “trust exchange”: Ahmed shared his worries; we provided corresponding solutions—and this is the foundation of long-lasting cross-border collaboration.

Appendix: Core Optimizations of Bottled Water RO Water Treatment System (Answering Ahmed’s 21 Questions)

| Ahmed’s Question | Initial Quotation Status | Revised Quotation Optimization (Concern Addressed) |

| 1. High-pressure pipelines: SS316L | Material not specified (only “stainless steel pipeline”) | Upgraded to SS316L; noted: “Corrosion-resistant, suitable for high-salt groundwater environments” |

| 2. RO permeate pipelines: SS316L | Same as “regular stainless steel” | Upgraded to SS316L; matches RO product water hygiene standards |

| 3. UPVC pressure pipes: PN16 class | Class not noted | Specified as PN16; noted: “Withstands 1.6MPa pressure, meets system pressure requirements” |

| 4. Pumps: Well-known brand (e.g., Grundfos) | Generic pump; brand not noted | Replaced with Grundfos CR series; attached Grundfos Pump Data Manual |

| 5. High-pressure pump material: SS316L | SS304 material | Upgraded to SS316L; noted: “Acid/alkali corrosion-resistant” |

| 6. FRP vessel rated pressure | 8bar | Increased to 10bar; noted: “Matches system maximum operating pressure” |

| 7. Cartridge filter housing: SS316L | Regular plastic housing | Upgraded to SS316L; meets food-contact requirements |

| 8. Pump/filter flow & pressure parameters | Only “Meets 500LPH” | Specific values provided:

– Pump: 500LPH flow, 1.2MPa design pressure, 0.8-1.0MPa operating pressure – Filter: 1.0MPa design pressure; noted: “Matches system stability requirements” |

| 9. Activated carbon ash/moisture | Not noted | Ash ≤5%, moisture ≤10%; attached Activated Carbon Test Report |

| 10. RO membrane: Dow/Hydranautics brand | Industrial RO membrane; brand not noted | Replaced with Dow LCLE-PRO-4040; attached Dow RO Membrane Parameter Sheet |

| 11. Technical manuals for all equipment | None | Attached 5 original documents:

1. Grundfos Pump Data Manual 2. Dow RO Membrane Specification 3. UV Disinfection Technical Document 4. Ozone System Manual 5. FRP Vessel Test Report |

| 12. RO membrane projection data | None | Attached Dow RO Membrane Flux Projection Sheet |

| 13. Chemical dosing configuration | None (not mentioned) | Clarified: “Not required for current small system; can be added if production expands” |

| 14. Backwash pump | None | Clarified: “Manual backwashing sufficient for small system; no pump needed” |

| 15. Sand/carbon media lifespan | Not noted | Sand filter: 1-3 years; activated carbon: 8-12 months |

| 16. UV dosage | Not noted | 40-60mJ/cm²; noted: “Compliant with WHO drinking water disinfection standards” |

| 17. Ozone/UV technical documents | None | Attached Ozone System Manual & UV Disinfection Technical Manual |

| 18. System interlock/automation | Basic manual control | Clarified: “Raw/product water tank level interlock + pressure interlock; attached control logic diagram” |

| 19. Flow/pressure analyzers | None | Clarified: “Not required for small system; can be added later” |

| 20. Food-grade coating for equipment | Not noted | Clarified: “All water-contacting components use food-grade coating; compliant with FDA standards” |

| 21. RO CIP system | None | Clarified: “Manual cleaning sufficient for small system; required for large systems” |

Looking for a customized 500LPH RO Water Treatment System or need a tailored quotation for your drinking water project? Contact Bella via +86 13544774483 or bella@swroplant.com—we’ll address your details and deliver a reliable cross-border solution