What Is a Brackish Water Reverse Osmosis (BWRO) System?

How Is BWRO Different From a Standard RO System?

| Water Source | Description | TDS Range (ppm) | Recommended RO System |

|---|---|---|---|

| Tap Water / Well Water / Borehole Water / River Water | Freshwater, low salinity | ≤ 1,500 | Standard RO System (Freshwater RO) |

| Brackish Water / Deep Well Water | Medium to high salinity | 2,000 – 19,000 | Brackish Water RO System (BWRO) |

| Seawater | High salinity | ≥ 20,000 | Seawater RO System (SWRO) |

Brackish Water RO System (BWRO) Process Flow

Advantages / Benefits of Brackish Water RO (BWRO) Systems

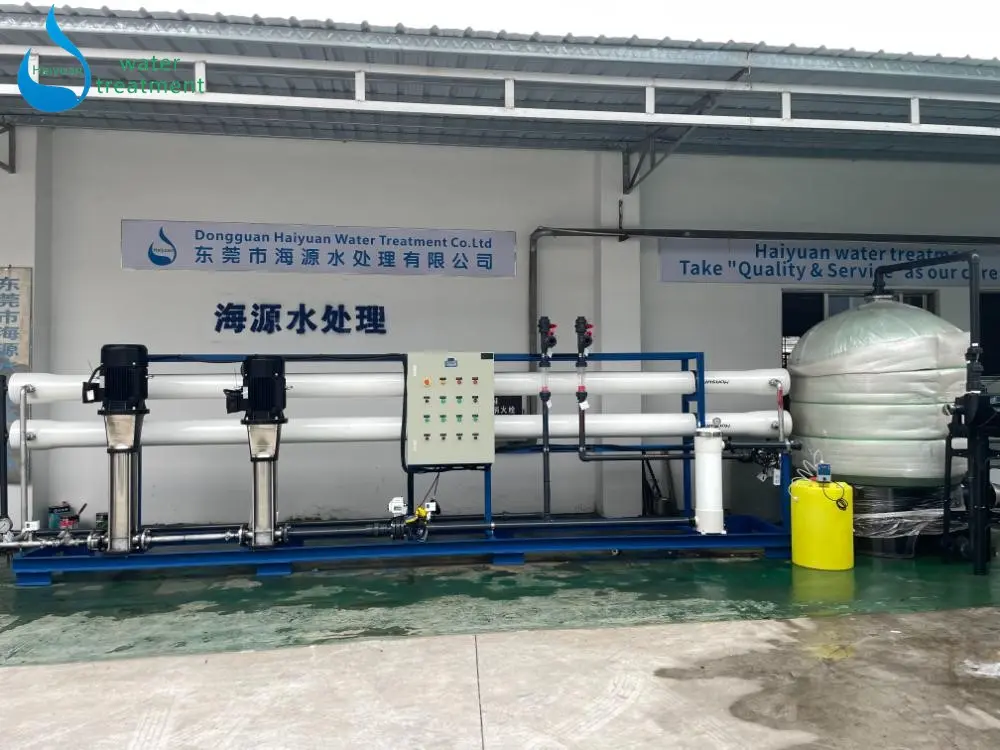

Can a Brackish Water RO System Be Customized?

Absolutely! Every customer has unique requirements. When designing a brackish water reverse osmosis (BWRO) system, we take into account site conditions, water quality reports, and specific capacity needs to provide a tailor-made solution.

1. System Capacity

-

Haiyuan BWRO systems can be designed for flow rates from 1,000 L/hr up to 50 m³/hr.

-

Customers can choose the capacity that fits their needs precisely.

2. Limited Installation Space

-

For clients with restricted site space, we can design compact, centralized systems that fit perfectly within the available area.

-

Providing accurate site dimensions ensures smooth installation and operation.

3. Containerized Solutions

-

BWRO systems can be installed directly inside 20ft or 40ft containers, offering a plug-and-play solution.

-

Containerized systems are ideal for sites with limited space and provide a controlled, optimal environment for stable operation.

4. Desired Product Water TDS

-

We can design the system to achieve specific TDS levels, whether for drinking water or industrial use.

-

The design ensures consistent water quality according to customer requirements through professional process engineering and ongoing consultation.

Applications of Brackish Water RO (BWRO) System

-

Industrial Process Water: Cooling water, production process water, and other industrial applications.

-

Drinking Water: Communities, schools, hotels, and sports stadiums.

-

Agricultural Irrigation: Providing clean water for crops and farmland.

-

Food & Beverage Industry: Bottled water plants, food processing, and beverage manufacturing.

What Determines the Price and Cost of a Brackish Water RO System?

The cost of a commercial Brackish Water Reverse Osmosis (BWRO) system largely depends on feed water quality and the required product water quality. Different water qualities and treatment requirements affect the system design, components, and overall cost.

Common Cost-Influencing Components

-

Chemical and pH Dosing – For water conditioning and scaling prevention.

-

Chlorination Dosing – Disinfection and microbial control.

-

Media Filter – Removes suspended solids and turbidity.

-

Activated Carbon Filter – Eliminates chlorine, organics, and odor.

-

Water Softener – Prevents scale formation on membranes.

-

Antiscalant & Antifouling Dosing – Protects membranes from scaling and fouling.

-

Advanced Control Systems – PLC, monitoring, and automation for stable operation.

-

Advanced Instruments – Disk filters, flow meters, TDS, pH, and conductivity monitoring.

-

Stainless Steel Skid or Frame – Ensures durable and corrosion-resistant construction.

-

Blending Systems – Optional, for adjusting product water quality.

-

Three-Phase Electrical System & Accessories – For industrial power requirements.

-

UV Sterilizer or Ozone Generator – Post-treatment for disinfection.

-

CIP (Clean-in-Place) System – For membrane cleaning and maintenance.

The more complex the pretreatment and post-treatment requirements, the higher the system cost. System size, production capacity, and automation level also significantly affect pricing.

Provide Us Your Information for a Free Quote

To help us provide a customized free quotation for your Brackish Water RO (BWRO) system, please provide the following information:

-

Required Production Capacity: What is the flow rate you need? (e.g., L/hr, m³/hr)

-

Feed Water Quality: Please specify the source water type (well, borehole, river, etc.) and provide a water quality report if available.

-

Power Supply: Voltage and frequency (e.g., 3-phase 380V, 50Hz).

-

Intended Use of Product Water: Drinking, industrial process, irrigation, etc.

-

Existing Process Requirements: Do you already have a confirmed process flow or specific design in mind?

Once we receive these details, we can provide a tailored solution and a free quotation that meets your requirements.

Get in Touch / Request a Free Quote

Click here to leave us a message, or contact us directly via:

-

WhatsApp / WeChat / Mobile: +8618825874379

-

Email: haiyuan@swroplant.com

Our team will respond promptly and provide a customized solution for your Brackish Water RO system.