What Is a Drinking Water Purification Plant and Why Does Your Project Need One?

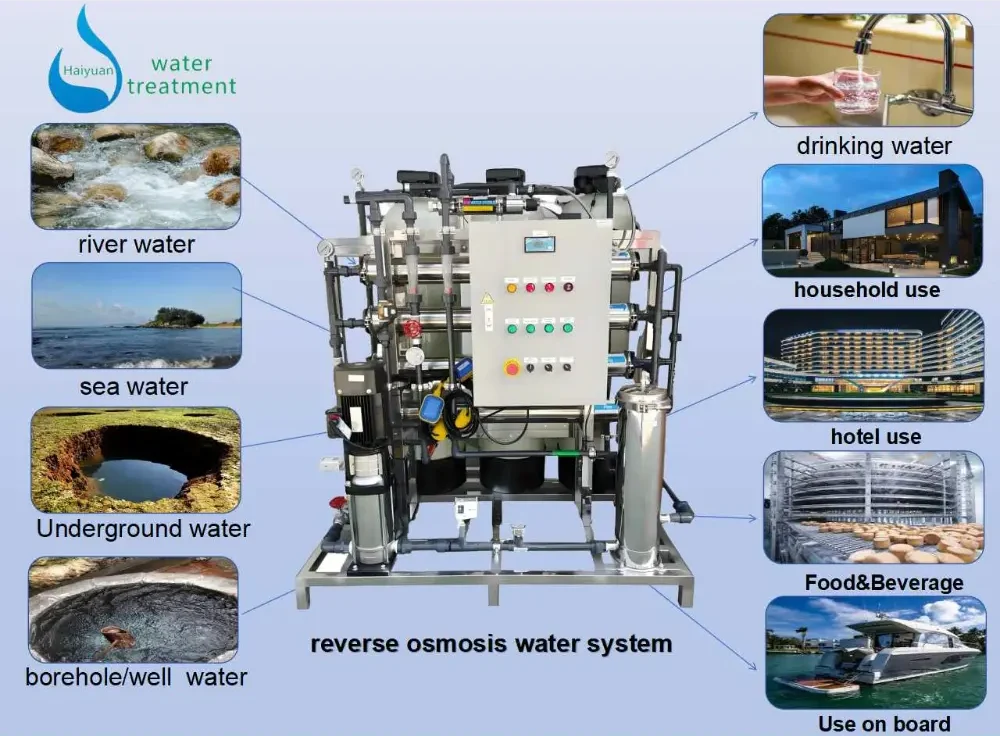

A drinking water purification plant offers a comprehensive and sustainable answer to these challenges. It transforms raw water from wells, rivers, lakes, or municipal networks into clean, safe, and great-tasting drinking water that meets or exceeds international standards. Whether you’re developing a municipal water project, supplying residential communities, or supporting industrial operations, understanding how these systems work — and why they’re essential — is key to making the right investment.

What Is a Drinking Water Purification Plant?

A drinking water purification plant is an integrated water treatment system designed to remove contaminants and deliver potable water suitable for human consumption and industrial applications. By combining multiple purification technologies, it eliminates bacteria, viruses, suspended solids, heavy metals, dissolved salts, pesticides, and other harmful substances.

Because water quality varies greatly from one source to another, purification plants are engineered to handle different levels of contamination. They are widely used in municipal water supply systems, residential housing projects, hospitals, schools, bottled water production, and industrial manufacturing facilities. In short, wherever clean water is required, a purification plant is the most efficient and scalable solution.

How a Drinking Water Purification Plant Works

Although specific system designs may differ based on water quality and capacity requirements, most drinking water purification plants follow a multi-stage process. Each stage targets particular impurities, ensuring thorough treatment and consistent water quality.

-

Pre-Filtration – The First Line of Defense

Raw water enters the system and first passes through coarse filters that remove large particles such as sand, silt, and rust. This step protects the downstream components and increases the system’s efficiency. -

Activated Carbon Filtration – Removing Chemicals and Odors

Next, the water flows through activated carbon filters that absorb chlorine, organic compounds, pesticides, and unpleasant tastes or odors. As a result, the water becomes cleaner and more palatable. -

Fine Filtration – Precision Protection

Before reaching the membranes, water passes through fine cartridge filters that capture smaller suspended solids. This stage ensures optimal performance and longevity of the membrane units. -

Membrane Filtration – The Heart of the System

At this stage, technologies like reverse osmosis (RO) or ultrafiltration (UF) remove up to 99% of dissolved salts, heavy metals, bacteria, and viruses. Because of this, the water produced is extremely pure and safe. -

Disinfection – Final Safety Step

To ensure absolute safety, ultraviolet (UV) sterilization or ozone disinfection is applied to destroy any remaining microorganisms. This guarantees that the water meets international drinking water standards. -

Storage and Distribution – Ready for Use

Finally, the treated water is stored in a hygienic tank and distributed directly for residential, commercial, or industrial use.

Key Components of a Drinking Water Purification Plant

A reliable system is built from high-quality, durable components that ensure stable performance and long service life. The main parts typically include:

-

Raw Water Pump: Delivers water from the source into the treatment system.

-

Multi-Media and Carbon Filters: Remove suspended particles, chlorine, and organic matter.

-

Cartridge Filter: Provides fine filtration and protects the RO membranes.

-

High-Pressure Pump: Supplies the pressure required for efficient membrane operation.

-

RO Membrane Modules: Perform the main purification by removing dissolved impurities.

-

UV Sterilizer or Ozone Generator: Provide final disinfection to guarantee safety.

-

PLC Control System: Monitors performance and automates system operation for ease of use.

Because all components are made from food-grade, corrosion-resistant materials, they ensure safe operation and minimal maintenance over time.

Why Your Project Needs a Drinking Water Purification Plant

Investing in a drinking water purification plant provides significant advantages for communities, industries, and businesses. Here’s why it’s a smart decision:

1. Safe, Reliable Water Supply

Because the system removes harmful contaminants, it ensures water quality that meets or exceeds WHO and national standards. This is critical for health, safety, and regulatory compliance.

2. Cost-Effective Operation

Producing purified water on-site is far more economical than purchasing bottled water. Over time, it significantly reduces operational costs and improves return on investment.

3. Customizable Capacity and Design

From small-scale 1000 LPH units for residential projects to large municipal plants exceeding 100 m³/h, systems can be tailored to match your exact capacity needs and water quality requirements.

4. Low Maintenance and High Durability

Because modern plants are designed with automation and self-cleaning features, they require minimal human intervention while ensuring long-term reliability.

5. Sustainability and Environmental Benefits

By reducing plastic bottle usage and water wastage, purification plants support sustainability initiatives and help organizations meet their environmental goals.

Applications Across Different Sectors

A drinking water purification plant is versatile and widely used in many industries and public sectors, including:

-

Municipal Water Projects: Centralized supply for cities and towns.

-

Industrial Manufacturing: High-purity water for food processing, pharmaceuticals, and electronics.

-

Public Institutions: Safe water for schools, hospitals, and government facilities.

-

Residential Complexes: Centralized drinking water solutions for apartments and housing estates.

-

Bottled Water Businesses: Consistent quality water for commercial bottling operations.

Customized Solutions for Your Unique Water Challenges

Because every water source is different, one-size-fits-all solutions rarely deliver the best results. That’s why we offer fully customized purification systems based on raw water quality, capacity requirements, site conditions, and budget.

For remote locations, containerized plants offer rapid deployment and easy installation. For large-scale infrastructure projects, turnkey systems include fully automated controls, remote monitoring, and real-time performance reporting. Regardless of the scale or application, we design each solution to deliver maximum efficiency and long-term value.

💧 Contact us today to discuss your project requirements and receive a tailored solution designed specifically for your water challenges. Together, we can build a future where clean, safe water is available to everyone.