How to Choose Large Scale Water Purification System

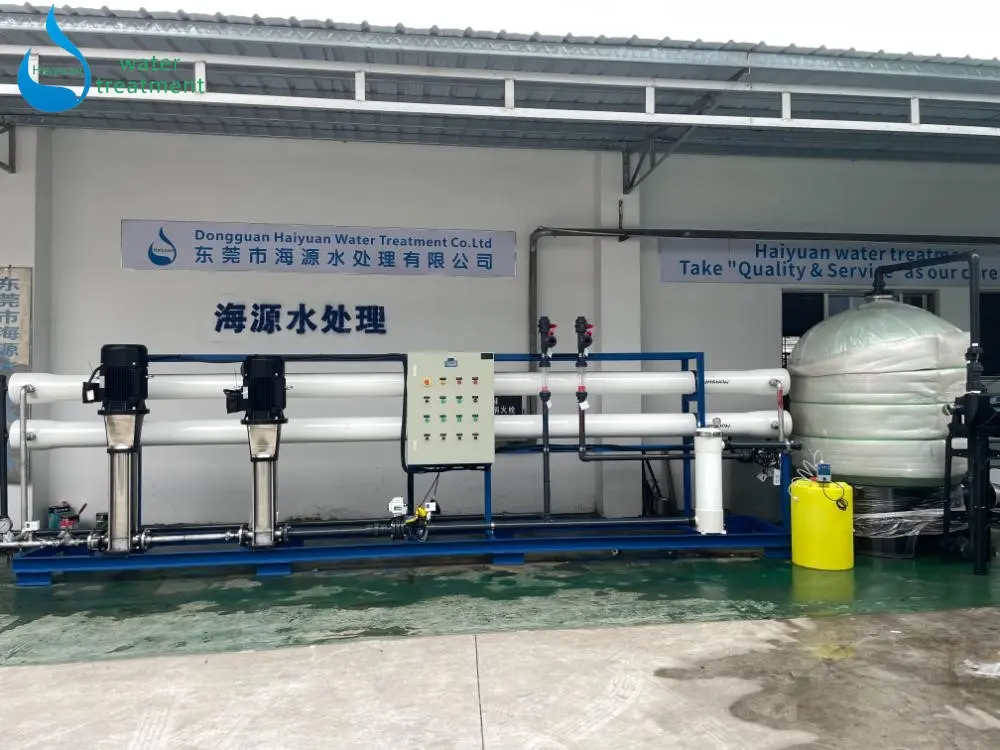

A Large Scale Water Purification System is an industrial or municipal water treatment solution designed to produce a high volume of clean, safe, and stable-quality water. It removes suspended solids, sediments, dissolved salts, heavy metals, organic matter, bacteria, and viruses from raw water sources such as river water, well water, brackish water, or seawater.

These systems are widely used in factories, communities, water stations, hotels, bottling plants, food processing, and agricultural irrigation.

Advantages of Large Scale Water Purification System

-

High output capacity – suitable for continuous 24/7 operation

-

Stable water quality – consistent TDS and purity

-

Efficient removal of contaminants – bacteria, salts, metals, organics

-

Energy-saving design – high-efficiency pumps & membranes

-

Long lifespan – durable materials (SS304/316)

-

Fully automatic control – PLC, flowmeters, pressure gauges

-

Easy installation – optional containerized, plug-and-play

-

Low operating cost

Process Flow of Large Scale Water Purification System

Raw water tank—booster pump—multi-media filter—activated carbon filter—softening filter—scale inhibitor—reduction dosing device—precision filter—high-pressure pump—RO—UV—product water tank

Process Flow Design Principles

The design of a water purification process depends on multiple factors, including the raw water quality, required water standard, and intended application.

-

For simple requirements and relatively clean raw water, the process flow can be straightforward.

-

For poor-quality water that needs very low TDS or ultrapure water, the process will include additional professional components and treatment steps to meet the required standard.

In other words, the process is always customized to ensure optimal water quality while keeping the system cost-effective and efficient.

Main Components of Large Scale Water Purification System

-

Raw water pump

-

Multi-media sand filter

-

Activated carbon filter

-

Water softener (optional)

-

Dosing system (coagulant, antiscalant, chlorine remover)

-

Cartridge filter

-

High-pressure pump

-

RO/UF/SWRO membrane system

-

Control panel (PLC/HMI optional)

-

Stainless steel pipes and valves

-

UV sterilizer or ozone system

-

Pure water tank

-

Containerized housing (optional)

Water Quality That the System Can Treat

A large-scale purification system can handle:

-

River water / lake water (high turbidity, organic matter)

-

Well water (TDS up to 5000–10000ppm depending on design)

-

Brackish water

-

Seawater (TDS 35000–45000ppm)

-

Industrial wastewater for reuse (with special design)

-

Drinking water supply

-

High-purity water (RO + EDI)

Installation and Footprint

Applications of Large Scale Water Purification System

-

Industrial manufacturing

-

Food & beverage factories

-

Bottled water production

-

Community drinking water supply

-

Agricultural irrigation

-

Hotel & resorts

-

Hospitals

Customizable Options

-

Capacity (1–50 m³/hour or more)

-

Pretreatment configuration

-

RO / UF / SWRO / EDI processes

-

Stainless steel or FRP material

-

Energy recovery device (for seawater)

-

Solar power supply

-

Container house (10ft / 20ft / 40ft)

-

Water tank size and material

-

Remote monitoring and PLC brand customization

-

Chemical dosing options

-

High recovery design

How to Choose the Right Large Scale Water Purification System?

1.Identify raw water type

River, well, brackish, or seawater → each requires different membranes and pretreatment steps.

2.Check water test report

Focus on TDS, turbidity, hardness, iron, manganese, and organics to determine the correct treatment design.

3.Define required capacity

Calculate daily usage and apply a safety factor to ensure stable supply.

4.Determine water quality standard

Options include drinking water, industrial process water, or ultrapure water.

5.Choose suitable purification process

UF for low-TDS surface water

RO for brackish water

SWRO for seawater

RO + EDI for ultrapure water applications

6.Select preferred installation type

Skid-mounted systems or fully containerized units for plug-and-play use.

7.Consider power availability

Check voltage, frequency, and whether diesel generator or solar power is required.

Contact Us

For more information about our Large Scale Water Purification Systems, customized solutions, or quotes, please contact our professional team. We provide tailor-made solutions to meet your water treatment needs.

Contact Information

-

📧 Email: haiyuan@swroplant.com

-

📞 Phone: +86 188 2587 4379