How Reverse Osmosis RO Water Plant Produce Drinking Water?

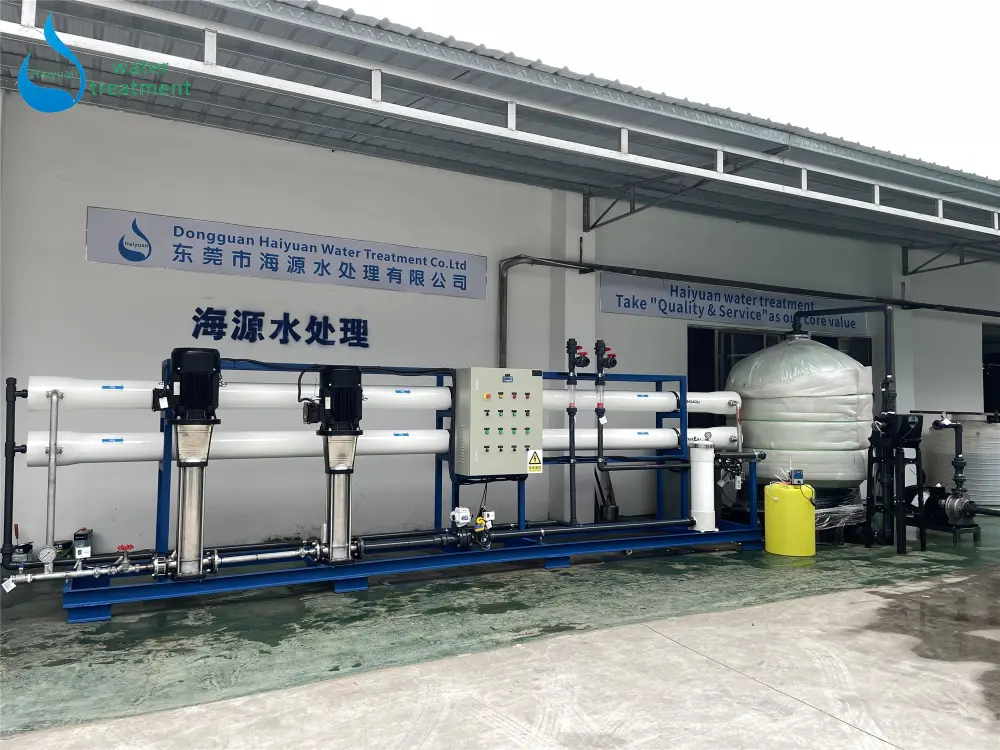

Haiyuan Reverse Osmosis (RO) Water Plant is an industrial and commercial water purification system designed to remove dissolved salts, minerals, heavy metals, bacteria, and other impurities from raw water.It uses high-pressure pumps to push water through a 0.0001-micron RO membrane, producing clean, safe, and low-TDS purified water.

Haiyuan provides fully customized RO water plants with capacities ranging from 1000 L/h to 50 m³/h, suitable for brackish water, well water, tap water, and seawater.

What Haiyuan RO Water Plant Can Do:

-

Produce safe drinking water for communities and cities

-

Treat well water with high TDS, hardness, iron, and manganese

-

Desalinate seawater for islands, ships, and coastal areas

-

Supply purified water for factories and industrial processes

-

Provide clean water for hotels, hospitals, schools, and farms

-

Support agriculture and irrigation

-

Serve as a complete containerized mobile water station

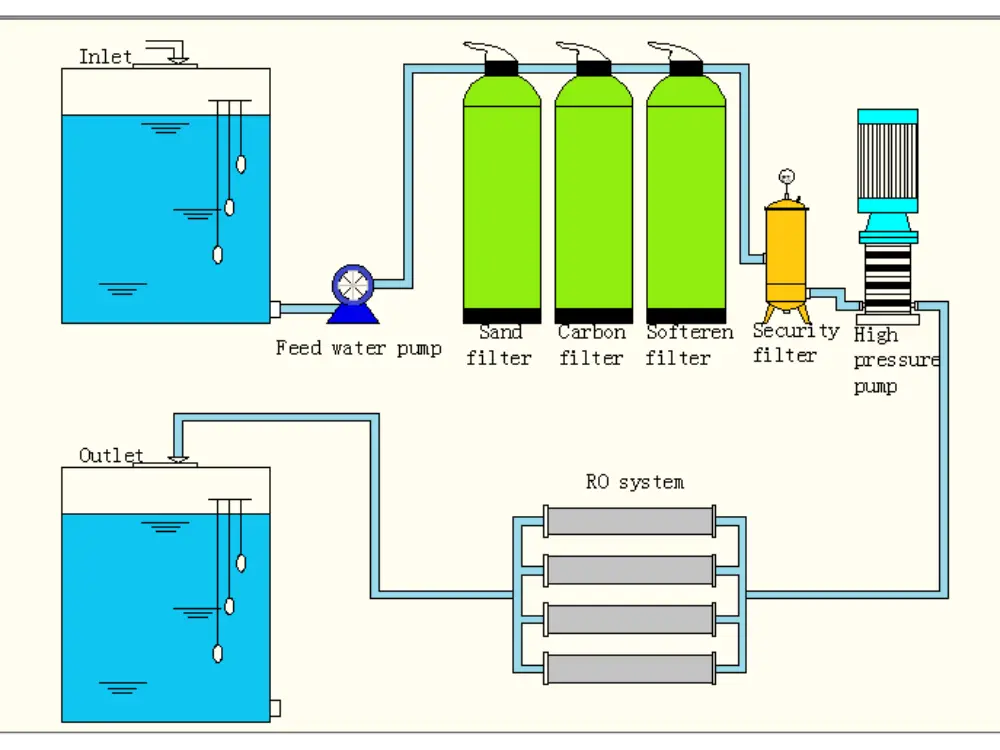

Reverse Osmosis RO Water Plant Process Flow

-

Raw Water Pump – Supplies raw water

-

Sand / Multimedia Filter – Removes turbidity and suspended solids

-

Activated Carbon Filter – Removes chlorine, organic matter, odor

-

Water Softener – Reduces hardness to prevent scaling.

-

Antiscalant Dosing – Prevents scale on RO membranes from minerals.

-

Cartridge Filter (5 µm) – Final protection before RO

-

High-Pressure Pump – Provides pressure for the RO membrane

-

RO Membrane System – 0.0001-micron core filtration

-

Clean Water Tank – Stores permeate water

-

Post-Treatment (Optional) – UV, ozone, mineralization

For raw water with good quality, such as low turbidity or low hardness, the sand filter or water softener stages can be reduced. For low-TDS water sources, the water can even go directly to the RO system without softening or antiscalant dosing, simplifying the process.

On the other hand, additional treatment steps can be added based on water quality requirements: UV disinfection for water with high microbial content, ozone or chlorine dosing for industrial sterilization or preservation, and mineralization or pH adjustment to improve the taste and health quality of drinking water.

Application of reverse osmosis RO water plant

| Application Area | Specific Applications |

|---|---|

| Drinking Water Supply | Communities, towns, villages, camps, schools, hospitals |

| Industrial Applications | Electronics, chemicals, pharmaceuticals, food & beverage, manufacturing, boiler feed water, cooling towers |

| Agriculture | Greenhouses, irrigation, livestock water, hydroponics |

| Commercial | Hotels, resorts, restaurants |

| Seawater Desalination | Islands, ships, fish farms, coastal communities |

Core Components & Optional Components

| Core Components (Standard) | Optional Components |

|---|---|

| Raw water pump | Water softener |

| Sand/multimedia filter | Antiscalant dosing system |

| Activated carbon filter (Determined by water quality) | CIP cleaning system |

| Cartridge / security filter | UV sterilizer / Ozone generator |

| High-pressure pump (CNP/Grundfos) | Mineralizer |

| RO membrane (DOW, Toray, Vontron) | Pre-RO sediment filter system |

| Stainless steel or FRP membrane housing | Booster pump |

| Control panel (PLC/automatic/manual) | 20ft/40ft containerized system |

| Pressure gauges, flow meters, conductivity meters | Solar power system |

| Piping and high-pressure fittings | Energy recovery device (for SWRO) |

In addition to the essential process steps, customers have the flexibility to choose additional accessories based on their specific needs, the quality of the raw water, and the intended use of the treated water. Of course, opting for just the basic process steps is also a great choice when working with a limited budget.

What Types of Raw Water Can be Treated?

| Raw Water Type | TDS Range | Common Sources | Treatment Type |

|---|---|---|---|

| Tap Water | 100–1,500 ppm | Municipal water supply, city water | Removes chlorine, sediments, impurities |

| Well Water | 500–10,000 ppm | Groundwater, wells, boreholes | Removes hardness, iron, manganese |

| Brackish Water (BWRO) | 2000–19,000 ppm | Coastal aquifers, rivers, lakes | Removes salts and dissolved solids |

| Seawater (SWRO) | 35,000–45,000 ppm | Oceans, seawater bodies | High pressure removes salt and minerals |

| Surface Water | 100–5,000 ppm | Rivers, lakes, reservoirs | Requires filtration for suspended solids and organics |

Key RO Plant Categories

-

Brackish Water RO (BWRO): Treats water with moderate salinity, often from groundwater or rivers.

-

Seawater RO (SWRO): High pressure desalination for seawater to produce freshwater.

-

Industrial RO: For large-scale industries requiring high volumes of purified water, e.g., food and beverage production, electronics, and pharmaceuticals.

-

Commercial RO: Smaller systems for commercial buildings such as hotels, offices, and restaurants.

-

Containerized RO: All-in-one RO systems in containers, perfect for remote or mobile applications.

-

Solar Powered RO: Ideal for regions without reliable electricity, using solar energy to operate the RO system.

Install Reverse Osmosis RO Plant Inside the Container

Besides installing the reverse osmosis RO water plant directly on-site, it can also be installed inside a 20-foot or 40-foot container.Containerized RO Systems are fully integrated and pre-installed RO water treatment systems,these systems are designed for easy transportation, fast installation, and operation in remote or off-grid locations.

-

Plug-and-Play:The system is ready to use as soon as it is powered on. No additional setup or assembly is required.

-

No On-Site Assembly:All components are pre-assembled and connected inside the container, reducing installation time and labor costs.

-

Protects the Equipment:The container provides a controlled environment, shielding the equipment from harsh weather and external damage, ensuring smooth operation.

-

Easy to Transport and Relocate:The containerized system is highly portable, making it easy to move to different locations as needed.

-

Multiple Applications:Suitable for various uses, including remote water supply, disaster relief, industrial sites, and more.

If you have the above requirements, containerized RO plant is a good choice. Of course, if you have a limited budget, you can also choose a second-hand container.

If you require a quote from Haiyuan, please provide the following information:

To help us recommend the most suitable system, please provide:

-

Desired Product Water Flow Rate (e.g., m³/hr, m³/day, L/hr, GPM, GPD)

-

Intended Use of Product Water (e.g., drinking, irrigation, industrial process, others)

-

Feed Water TDS and Source (e.g., borehole, seawater, brackish water, lake water, tap water)

-

Power Supply Requirements (e.g., 110V, 220V, 380V, 415V, 460V; 50 or 60 Hz; three-phase)

-

Water Analysis Report (required for borehole, lake, or seawater; not required for tap water)

Our Services and Support:

Multi-language Technical Support & After-sales Service (1 year included)

OEM/ODM Customization available to meet your specific requirements

Installation & Commissioning Guidance provided for smooth system setup

Reliable Export Packaging & Shipping with extensive international experience