Understanding the Key Steps of the Advanced RO Plant

At Haiyuan Water Treatment Company, we believe that understanding how a system works is key to truly appreciating its value. Therefore, today we want to share with you the detailed working process behind our reliable RO plant and explain why it is trusted by many industries worldwide.

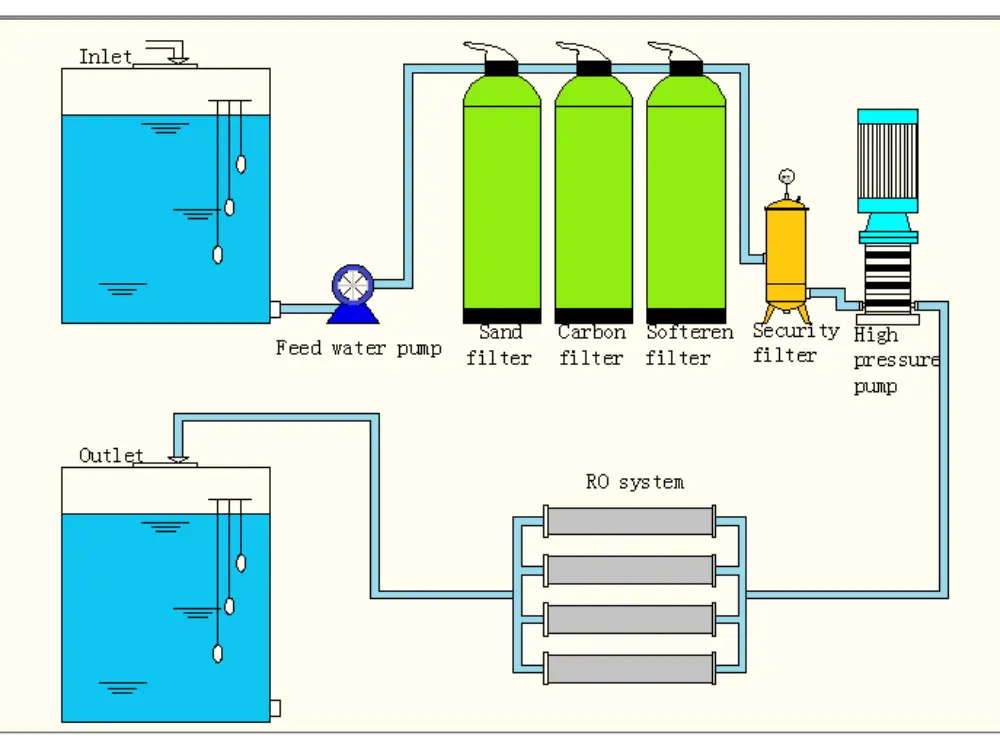

1. Raw Water Intake and Pretreatment for RO Plant

Every great RO plant starts with quality input. Our system begins by drawing raw water — whether it’s well water, river water, or seawater — into the intake unit. Since water quality varies greatly, pretreatment is essential to ensure smooth operation downstream. To achieve this, we employ filtration and anti-scalant dosing to remove sediments, chlorine, and other particles that could potentially harm the membranes.

Pretreatment mainly includes the following steps:

Sand Filter (Required)

Function: Removes suspended solids, sediments, and large particles from raw water.

Advantages: Protects downstream equipment from clogging and damage; extends membrane lifespan; improves water clarity.

Activated Carbon Filtration (Optional, depends on water quality)

Function: Adsorbs chlorine, organic compounds, and unpleasant tastes or odors.

Advantages: Prevents membrane damage caused by chlorine; improves water taste and odor; removes harmful organic contaminants.

Water Softening (Optional, depends on water hardness)

Function: Reduces hardness by removing calcium and magnesium ions.

Advantages: Prevents scale formation on membranes and pipes; improves system efficiency and reduces maintenance costs; extends membrane life.

Anti-scalant Dosing Tank (Optional, depends on client needs)

Antiscalant dosing is part of the pretreatment stage. It is added before the water reaches the RO membranes to prevent scale formation on the membrane surface, thereby ensuring stable system operation.

2. High-Pressure Pump System in RO Plant Operation

Next, the pretreated water is pumped at high pressure through the RO membranes. This is a critical step, as the high-pressure pump provides the necessary force to overcome the natural osmotic pressure, allowing clean water molecules to pass while leaving impurities behind.

Moreover, choosing the right materials for high-pressure pumps is essential to ensure durability and corrosion resistance, especially when handling different types of feed water such as brackish or seawater. Common materials used include stainless steel grades SS304 and SS316, both offering excellent corrosion resistance and mechanical strength.

3. Reverse Osmosis Membrane Separation

The reverse osmosis membrane serves as the heart of any RO plant. Its main function is to separate dissolved salts, contaminants, and impurities from the water, allowing only pure water molecules to pass through. This selective barrier ensures the production of clean, high-quality water.

Key advantages of RO membranes include:

High Rejection Rate: Effectively removes up to 99% of dissolved salts, bacteria, viruses, and organic compounds.

Energy Efficiency: Modern membranes operate at lower pressure, reducing energy consumption.

Durability: Designed to withstand varying water qualities and operating conditions for extended periods.

Compact Design: Space-efficient, allowing modular system configurations.

Our company offers RO membrane housings in two standard sizes: 4040 and 8040. The 4040 membranes are ideal for small to medium capacity systems, whereas the 8040 membranes are designed for larger industrial applications, providing higher flow rates and greater efficiency.

4. Disinfection Stage: UV and Ozone Disinfection

UV and ozone disinfection are regular process steps within the water treatment flow. They are typically installed after the RO membranes to provide final disinfection and ensure water safety.

-

UV Disinfection System: Installed after the RO permeate, it directly inactivates microorganisms in the purified water to ensure the water meets hygiene standards.

-

Ozone Disinfection System: Depending on the process design, it can be installed in the raw water pretreatment stage (to control biofilm and organic matter) or commonly used after the RO permeate for deep disinfection and oxidation.

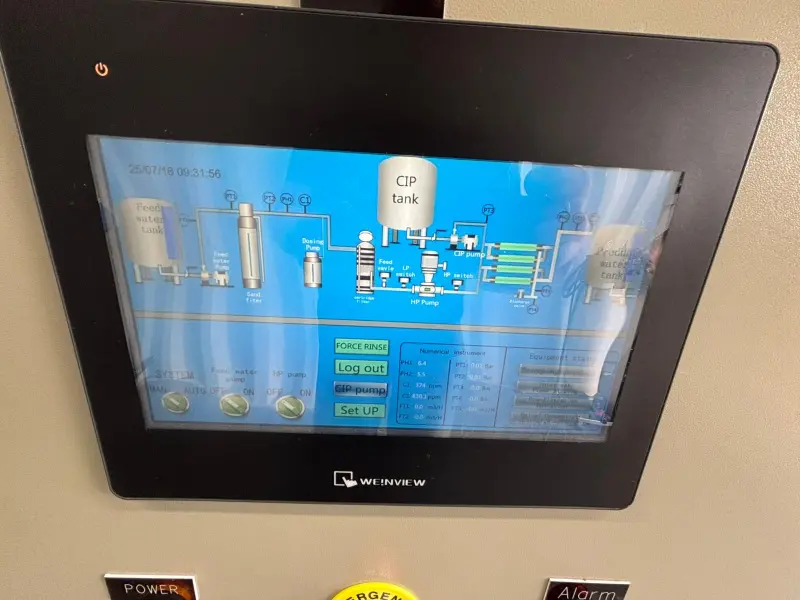

5. Automated Control System for Efficient RO Plant Management

The control system acts as the brain of the RO plant, responsible for monitoring and managing the entire water treatment process. Equipped with programmable logic controllers (PLC) and user-friendly interfaces, it automates operations such as pump start/stop, pressure regulation, flow rate adjustments, and fault detection.

The advantages of this automation include:

-

Real-time monitoring of key parameters (pressure, flow, conductivity)

-

Automatic alarms and shutdowns to protect equipment

-

Data logging for performance analysis and maintenance planning

-

Remote control and integration capabilities for smart plant management

As a result, this system ensures stable operation, reduces manual intervention, and enhances overall reliability.

6. Operation & Maintenance: CIP (Chemical Cleaning)

The Chemical Cleaning System, also known as CIP (Clean-In-Place), is designed to clean RO membranes without requiring disassembly. This automated process uses specially formulated cleaning chemicals to remove scale, biofouling, and other contaminants that accumulate on membrane surfaces over time.

It is important to note that CIP is not part of the continuous water treatment flow but rather a periodic maintenance procedure. It is performed when membrane performance declines, requiring system shutdown for cleaning to restore efficiency.

Why Choose Haiyuan’s RO Plant?

-

Customizable Design: Tailored capacity and components based on your water source and output needs.

-

Energy Efficiency: High-pressure pumps and membranes are selected to reduce power consumption.

-

Durability: High-quality materials ensure the system withstands harsh operating conditions.

-

Smart Control: Automated panels monitor system performance and alert operators to maintenance needs.

Thank you for reading. If you have any questions about our RO plant solutions, or if you need a customized design for your specific water treatment needs, feel free to contact our team.