Why Choose Ultrafiltration(UF) System Water Filtration?

Ultrafiltration (UF) membrane system, also known as UF water purification plants, operate as pressure-driven filtration processes designed to remove suspended solids, colloids, and particulate matter from water. In many applications, a UF membrane system can effectively replace conventional pretreatment methods such as sand filters, activated carbon filters, and mechanical filtration.

Compared with reverse osmosis (RO) membranes, UF membranes have higher permeability, allowing greater water flow at lower pressures. However, it is important to note that ultrafiltration alone cannot reduce Total Dissolved Solids (TDS). Since the pore size of UF and microfiltration (MF) membranes is relatively large, dissolved salts and minerals will pass through and remain in the water.

How Does the Ultrafiltration Process Work?

The UF membrane system is a pressure-driven process. When water is pushed through the hollow-fiber or flat-sheet membranes, unwanted particles and microorganisms are trapped on the membrane surface while clean water passes through. This makes ultrafiltration an excellent pretreatment method for reverse osmosis (RO) systems, desalination plants, and other advanced water treatment applications.

Operation Specifications of Ultrafiltration System

| Parameter | Value |

|---|---|

| Power Supply | 380/460V, 3 Phase, 50Hz/60Hz |

| Operating Temperature | 25°C (max. 40°C) |

| Total Organic Carbon (TOC) | < 10 mg/L (max. 40 mg/L) |

| pH Range | 6–9 (2–11 during cleaning) |

| Total Suspended Solids (TSS) | < 50 mg/L (max. 100 mg/L) |

| Backwash Frequency | 20–60 minutes |

| Turbidity | < 50 NTU (max. 300 NTU) |

| Free Chlorine (Cl₂) | ≤ 0.5 ppm |

| Chemical Oxygen Demand (COD) | < 60 mg/L |

Key Features of Ultrafiltration Membranes:

-

Removes turbidity, suspended solids, and bacteria

-

Higher permeability than reverse osmosis membranes

-

Operates at lower pressure, saving energy

-

Provides consistent water quality regardless of feed water conditions

If your raw water has low TDS and is already clean, and you want to retain essential minerals for drinking purposes, a UF mineral water filtration system is the right choice for you.

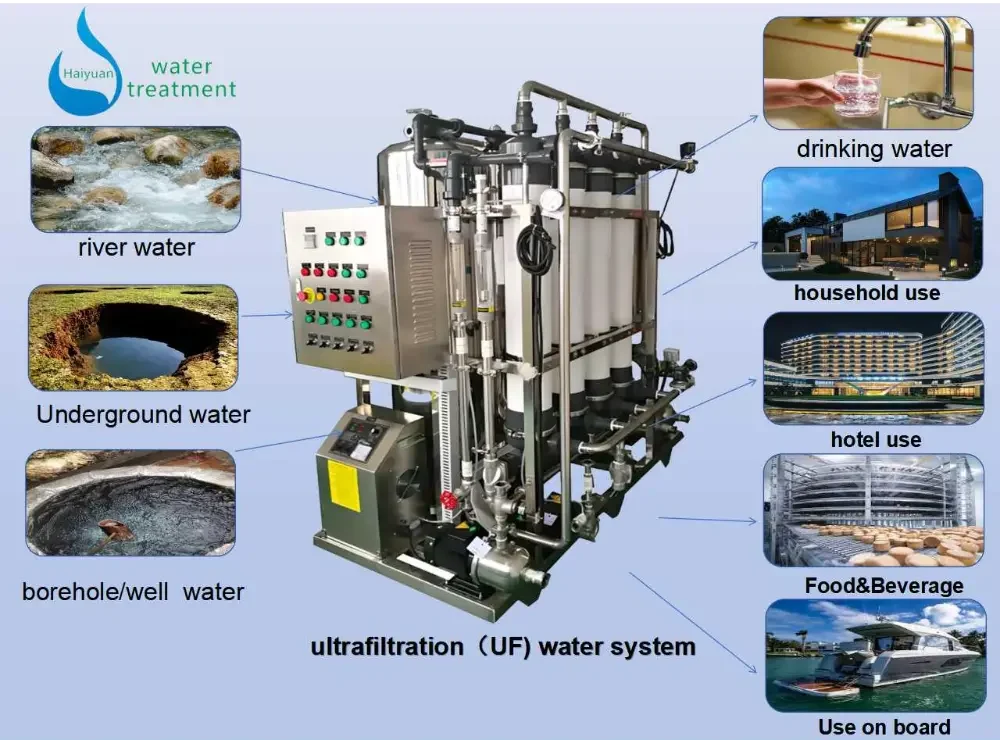

Applications of Ultrafiltration System

-

Drinking Water Supply – Ensures safe and clean water for households and communities by removing pathogens and turbidity.

-

Industrial Water Treatment – Provides high-quality process water for manufacturing, food & beverage, and pharmaceutical industries.

-

Pretreatment for Reverse Osmosis and Desalination – Protects RO membranes from fouling, extending system lifespan and improving efficiency.

-

Bottled and Packaged Water Production – Delivers consistent clarity and purity required for commercial bottled water plants.

Benefits of Ultrafiltration Water Purification Plant

-

Reliable Water Quality – Produces crystal-clear water free from pathogens and impurities.

-

Cost-Effective Operation – Requires less energy and fewer chemicals compared to traditional processes.

-

Compact Design – UF plants take up less space and can be easily integrated into containerized water treatment systems.

-

Versatile Applications – Suitable for drinking water production, wastewater reuse, food and beverage industry, pharmaceuticals, and irrigation.

Haiyuan Customized Water Treatment Systems

Haiyuan specializes in customized water treatment solutions, including reverse osmosis systems, ultrafiltration units, seawater desalination, containerized RO plants, and solar-powered purification systems. With rich experience and flexible design, we provide reliable equipment for both commercial and industrial applications.