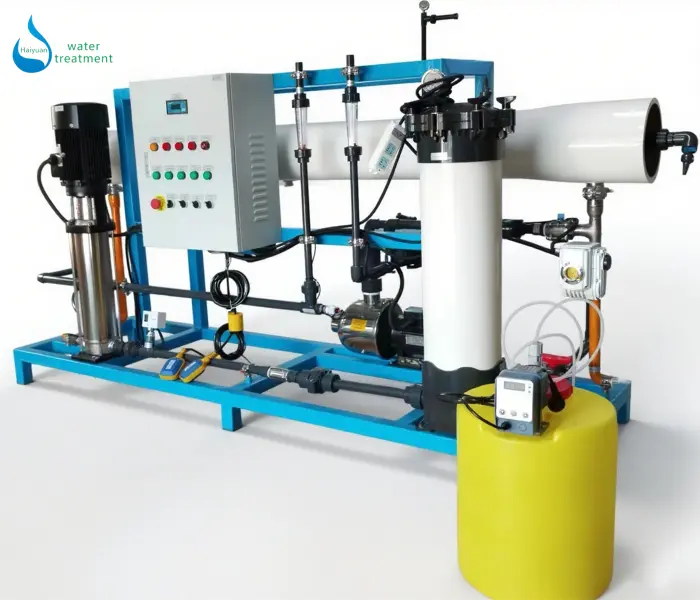

What is a Water Purification Plant Made Of?

Introduction

A water purification plant is a complete system designed to remove impurities and harmful substances from raw water, making it suitable for drinking, industrial, or agricultural use. But what exactly makes up a water purification plant? Let’s break down its main components and how they work together.

Water Purification Plant Process Flow

Here is the typical flow sequ ence of a water purification plant:

1. Standard Flow

Raw Water Tank → Booster Pump → Multi-Media Filter → Scale Inhibitor → Precision Filter → High-Pressure Pump → RO (CIP) → Product Water Tank

2. Extended Flow (with Advanced Treatment)

Raw Water Tank → Booster Pump → Multi-Media Filter → Activated Carbon Filter → Water Softener → Scale Inhibitor → Precision Filter → High-Pressure Pump → Reverse Osmosis (RO, CIP) → UV Sterilizer → Product Water Tank (with Ozone Sterilization)

-

The standard flow is suitable for general fresh water treatment, such as well water and municipal water, where TDS and contamination levels are moderate.

-

The extended flow is designed for higher-quality requirements, ideal for drinking water projects, food & beverage production, or industrial applications that demand extra protection and disinfection.

Introduction and function of each part

Raw Water Tank

Stores incoming raw water from the source. Provides a buffer to ensure stable supply for subsequent treatment stages.

Product Water Tank

Stores treated water, ready for distribution or use, ensuring a consistent supply.

2. Booster Pump

Increases water pressure from the raw water tank to feed the filters efficiently.

3. Multi-Media Filter

Removes suspended solids, sand, and larger particulates through layered media filtration (e.g., sand, anthracite, gravel).

4. Activated Carbon Filter

Adsorbs chlorine, color, odor, and organic compounds, improving water taste and protecting downstream RO membranes.

5. Water Softener

Reduces water hardness by exchanging calcium and magnesium ions with sodium, preventing scale formation on RO membranes.

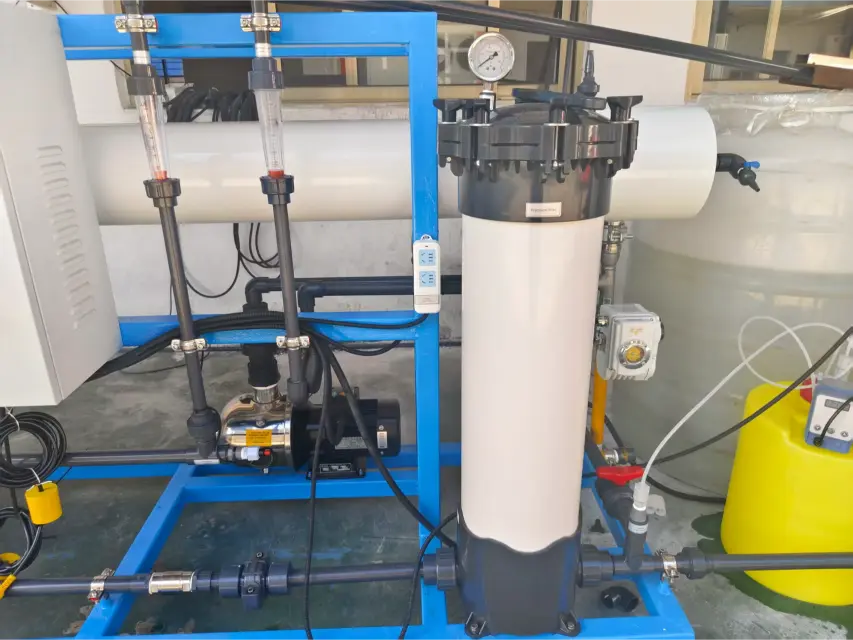

6. Scale Inhibitor

Chemically prevents scale formation by interfering with mineral crystallization, extending membrane lifespan.

7. Precision Filter (Cartridge Filter)

Removes fine particles (usually 5 μm or smaller) to protect high-pressure pumps and RO membranes.

8. High-Pressure Pump

Supplies the required pressure for reverse osmosis, ensuring efficient separation of dissolved salts and impurities.

9. Reverse Osmosis (RO, CIP)

Removes dissolved salts, bacteria, and other impurities using semi-permeable membranes. CIP (Cleaning-in-Place) allows periodic cleaning to maintain efficiency.

10. UV Sterilizer

Uses ultraviolet light to inactivate bacteria and viruses, providing an additional layer of disinfection after RO.

11. Ozone Sterilization

Optional final sterilization for stored product water, effectively killing remaining microorganisms and extending shelf life.

Applications of Water Purification Plant

-

Industrial Water: Manufacturing, electronics, chemical industries; boiler feed and process water.

-

Agriculture: Irrigation and greenhouse water to reduce soil salinity.

-

Drinking Water: Communities, schools, hotels; safe and clean water.

-

Seawater & Brackish Water: Small to medium desalination projects.

-

Food & Beverage: High-quality water for production.

Advantages of Water Purification Plant

-

Efficient Filtration: Removes solids, salts, odors, and microorganisms.

-

Longer Equipment Life: Softeners and scale inhibitors protect RO membranes.

-

Stable Water Quality: Precision filters and RO ensure consistent output.

-

Safe Disinfection: Optional UV or ozone sterilization.

-

Flexible & Customizable: Can add activated carbon, softeners, or dual disinfection.

-

Energy Saving: Low energy use; can integrate solar power.

Conclusion

A water purification plant is made of interconnected components that work together to ensure reliable and safe water treatment. From pretreatment and chemical dosing to reverse osmosis and final storage, every step plays a vital role.

By understanding what a water purification plant is made of, businesses and communities can select the right solution that matches their water source, capacity requirements, and quality standards.

Haiyuan Water Treatment Company specializes in customized water purification and desalination systems, with 20 years of manufacturing experience. If you have any needs, please feel free to contact us.