commercial reverse osmosis system ro system guide

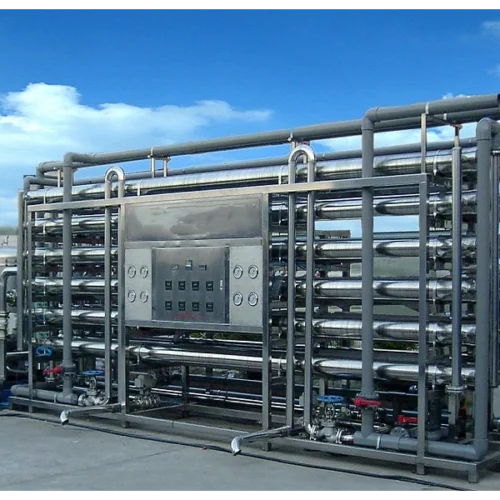

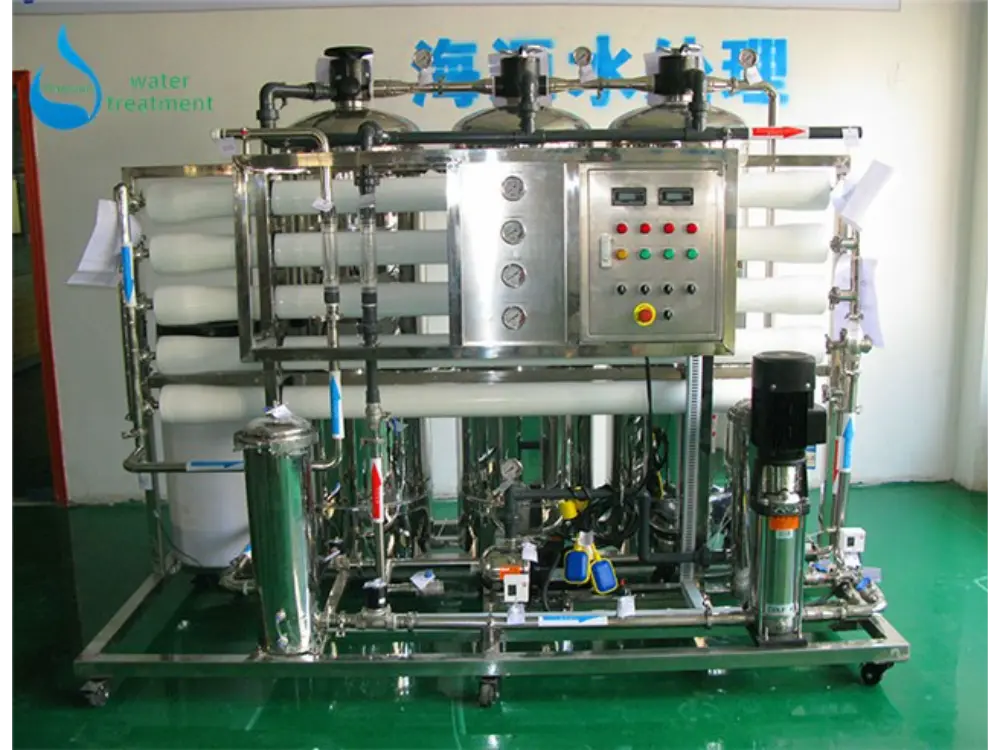

Haiyuan’s commercial reverse osmosis system is a compact, energy-efficient solution for treating seawater, brackish water, tap water, and drinking water. It is ideal for various applications including agriculture, boiler feed, hotels, marine use, disaster relief, food and beverage production, hospitals, restaurants, and offshore facilities. The system offers high recovery rates and reliable performance.

Haiyuan provides both standard and customized reverse osmosis systems designed specifically for commercial applications, with capacities ranging from 800 GPD to 6000 GPD. These systems deliver high-purity water at a competitive cost and are built with advanced engineering to ensure precision and adaptability to various water treatment needs.

1. Design basic of commercial reverse osmosis system

To design the most efficient system, we consider your specific feed water quality and output water standards. Below is a typical design example:

-

Feed Water Source: Rig water (high TDS up to 20,000 ppm)

-

Target Water Quality: Treated drinking water, TDS ≤ 300–400 ppm

-

Recovery Rate: Optimized to reduce wastewater while protecting membranes

-

Pre-treatment Required: Sand filter, activated carbon, and optional softener

All systems are tailored to the operating environment and local water chemistry to ensure long-term performance.

2. Client supply basic condition of Commercial RO system

Floor smooth, floor ground has drain trench.

Water quality basic steady, pressure steady.

3.Control method of Commercial reverse osmosis system

– Whole system use full/semi automatically control model, both model can be exchanged accordingly.

– Sand Carbon filter & water softener with auto and manual back flush.

– The RO system automatic flushing at each startup and shutdown.

– High water level auto stop, low water level auto start.

– Pump protected without water.

– Protected when no power, poor power, larger electrical current, leakage, short circuit.

4.Process flow of Commercial reverse osmosis system:

feed water tank →Feed water pump → mutimedia filter(sands filter) →Antiscalant filter → →Security filter→RO permeat tank→product water tank (prepared by user )

| Step | Description | Function |

|---|---|---|

| Feed Water Tank | Storage tank for raw water before treatment. | Holds untreated water for processing. |

| Feed Water Pump | Pump that moves water from the feed tank to the next stages of treatment. | Maintains flow and pressure to the system. |

| Multimedia Filter (Sand Filter) | Filter containing multiple layers (sand, anthracite, gravel) to remove large particles. | Removes suspended solids, dirt, and larger contaminants. |

| Antiscalant Filter | Introduces antiscalant chemicals to prevent scaling on RO membranes. | Prevents scaling from minerals like calcium carbonate. |

| Security Filter | A fine filter that ensures small particles are removed before RO treatment. | Protects the RO membranes from fine debris. |

| RO Permeate Tank | Tank where purified water from the RO system is stored. | Stores treated water after passing through RO. |

| Product Water Tank | Final storage tank for the clean, treated water, ready for use. | Holds the end product—clean water for consumption or industrial use. |

The following accessories are optional:

| Component | Description | Benefits |

|---|---|---|

| UV Sterilizer | Provides additional disinfection to eliminate harmful bacteria. | Ensures water safety for drinking or industrial use. |

| Ozone Treatment | Enhances purification with ozone, improving the overall water quality. | Effective for treating challenging water sources with high levels of contaminants. |

| CIP (Clean-In-Place) System | Automatic membrane cleaning system that maintains efficiency. | Reduces downtime and extends the lifespan of RO membranes. |

| Solar Power System | Enables off-grid operation using renewable solar energy. | Perfect for remote or eco-conscious applications. |

| Control Panel | Advanced touch screen interface with PLC for real-time monitoring. | User-friendly and easy to operate for monitoring system health and performance. |

Our company specializes in the production of customized water treatment equipment. Whether it is the capacity, process flow, installation size, etc., it can be designed and produced according to the needs of users.

capacity range: 1000L to 100m3/hour

To recommend the most suitable system for your needs, please provide the following details:

-

Required product water output (e.g., m³/hr, m³/day, L/hr, GPM, or GPD)

-

Intended use of the treated water, such as for drinking, irrigation, industrial processes, or other applications

-

TDS (Total Dissolved Solids) level of the feed water, and the water source type (e.g., borehole, brackish, seawater, lake, etc.)

-

Electrical requirements (e.g., 380V/440V/460V, 50Hz or 60Hz, 3-phase)

If you are interested in our commercial reverse osmosis system or need a custom solution, please feel free to contact us:

-

WhatsApp / WeChat: +86 18825874379

-

Email: haiyuan@swroplant.com

We are here to provide you with professional water treatment solutions.

👉To watch more product videos, please click here.

Why Choose Haiyuan?

-

Over 15 years of experience in water treatment system design and export

-

Proven quality with international standards compliance (CE, ISO, etc.)

-

Professional technical support and fast response service

-

Affordable cost with factory-direct pricing

-

Systems shipped worldwide to customers in over 30 countries